Verschiedene langlebige Wasser Jet Küche Arbeitsplatte Schneidemaschine

- Verpakung:

- Soft-Paket oder andere verhandelt von beiden Seiten Wasser Jet Küche Arbeitsplatte Schneidemaschine

- Marke:

- KOPF-Wasserstrahl-Küchenarbeitsplatte

- Ort Von Zukunft:

- Liaoning, China (Festland)

- Versorgungsmaterial-Fähigkeit:

- 20 Set/Sets per Month water jet kitchen countertop cutting machine

Basisinformation

Modell: HEAD3020BA/HEAD38030Z

Produktbeschreibung

Max Schneidstärke 100mm

Neues Produkt

380Mpa Druck

Durable

Wasserstrahl-Küche Arbeitsplatte Schneidemaschine

Produktbeschreibung Wir sind führende Hersteller von New Produkt Wasser Jet Küche Zähler Schneidemaschine in China

Wir bieten neue Produkt Wasserstrahl Küchentisch Schneidemaschine:

Quarz-Arbeitsplatten ist aus Quarz, der Vorteil von Quarz ist verschleißfest, gute Kopf Widerstand, verschiedene Küche Arbeitsplatten, nahtlos, langlebig.

Intensifier Pump of Various durable water jet kitchen countertop cutting machine | |

1.Pumps are imported from American Accustream company with advanced & reasonable structure and high stability. | |

2. Integrated heat exchanger, high heat exchange ratio and good effect, control the temperature of the hydraulic oil within the limit | |

3. Two-stage water filter(5um,1um,0.45um)minimizes the damage of impurities to high pressure seals, nozzles and other parts. | |

4.Two step-up water supply to make sure the pressure, automatic alarm and protection function when inadequate avoid the damage | |

5.Multiple filter for outlet oil and return oil, pollution alarm, oil cooling and oil temperature alarming ensure the continuous operation | |

6.Flexible connection between main motor pump eliminates eccentricity and absorbs vibration ensure its long-term reliable operation. | |

7. Large capacity accumulator, assuring the system pressure much more stable, cutting efficiency much higher | |

Model |

HEAD38030Z |

Intensifier |

USA imported |

Method of Direction Regulation |

Electronic Direction Regulation |

Max cutting pressure |

380MPA |

Continuous working pressure |

330Mpa |

Max oil pressure |

21Mpa |

Max water discharge |

3.7L/min |

Max oil discharge |

90L/min |

Power Source |

380V/50HZ |

Max diameter of orifice |

0.3mm |

Cutting table of Various durable water jet kitchen countertop cutting machine | ||||||||

Item |

Character |

|||||||

Machine type |

Bridge style and Cantilever style |

|||||||

Way of drive |

Servo drive( drives and motors are Yaskawa brand from Japan |

|||||||

Ball screw and linear guide |

ABBA brand from Taiwan |

|||||||

Processing range: |

Bridge style: X axis 2000mm-30000/ Y axis 2000mm-6000mm |

|||||||

|

Cantilever style: X axis 1000mm-1500 Y axis 2000mm-4000mm |

|||||||

Z-axis travel journey |

150mm |

|||||||

Controlling accuracy |

0.01mm |

|||||||

Cutting accuracy |

0.1mm |

|||||||

Re-position accuracy |

0.02mm |

|||||||

Max traveling speed |

6000mm/min |

|||||||

Structure type ( Bridge type) | ||||||||

HEAD2040BA |

HEAD2060BA |

HEAD3020BA |

HEAD3040BA |

HEAD3060BA |

HEAD4020BA |

|||

2000mm*4000mm |

2000mm*6000mm |

|

3000mm*2000mm |

3000mm*4000mm |

3000mm*6000mm |

4000mm*2000mm |

||

Structure type ( Cantilever type) |

||||||||

HEAD1020BB |

HEAD1520BB |

HEAD1525BB |

HEAD1530BB |

HEAD1540BB |

HEAD1540BB-F |

|||

1000mm*2000mm |

1500mm*2000mm |

1500mm*2500mm |

1500mm*3000mm |

1500mm*4000mm |

1500mm*4000mm |

|||

CNC Controller of Various durable water jet kitchen countertop cutting machine |

1. Industrial control computer: high reliability, convenient man-machine dialogue, real-time control of the cutting process |

2. CNC control, apply 19 inch LCD. facilitate operators to observe and reduce visual fatigue. |

3. Appropriate height of operating desk, reasonable display angle, and 180-degree horizontal rotation for easy operation and viewing |

4. Replace the relay with PLC, with a computer communications, flexible control |

5. Professional waterjet cutting software, easy to operate , easy to learn, and practical. |

6. Adapt industry wireless handle ,make the tool setting easy ,exact. |

7. Support DXF file ,can use AUTOCAD to produce DXF file |

8. use IPC and the professional software based on windows XP |

| Advantages of Various durable water jet kitchen countertop cutting machine |

| 1) Cold cutting without thermal influences. |

| 2) Flexible processing of virtually all materials with consistent high quality. |

| 3) Material-saving production due to reduced cutting width and the nesting of several parts on a single sheet. |

| 4) Maximum degree of material utilization due to the smallest of part separation distances (partially free of burrs) |

| 5) Tension-free processed parts due to minimal cutting force. |

| 6) Environmentally friendly and clean production without poisonous gases. |

| Various durable water jet kitchen countertop cutting machine can cut range of materials : |

| 1) Granite |

| 2)Metal |

| 3)Glass |

Um die Maschinenqualität zu gewährleisten, führen wir strenge und professionelle Qualitätskontrolle durch.

| Test whether the equipment cooling system work normally. |

| Test the hydrographic and hydraulic seal |

| Test whether the pressure fluctuations is stable, pressure amplitude records. |

| Connect each typemachine with rated pressure,then test actual cutting test |

| Test the scram function work normally |

| Test the oil pump and high pressure on the control panel button is working correctly. |

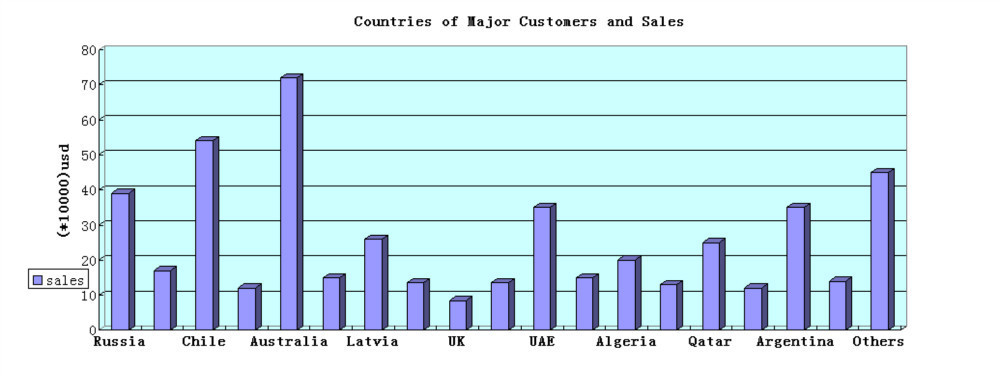

Till 2014 , the country name list HEAD had exported machine to as following : |

Asia :Vietnam, Sri Lanka, Malaysia, Philippines ,Iran,Thailand, UAE ,Qatar ,Iraq |

| Europe:Russia ,Austria,Latvia,Finland,Germany ,Switzerland, UK ,Ukraine ,Romania |

| America:USA ,Brazil ,Argentina ,Ecuador,Chile , Mexico, Canada |

| Oceania:Australia |

| Africa :South Africa ,Algeria |

Unsere Leistungen

,

,

| Head Waterjet has excellent quality and appropriate service . |

| Head has been very famous manufacturer in china since founded till now , |

| after-sale engineers offer excellent service to more than 20 countries clients , |

| and gain our clients high praise and trust . |

| UHP Intensifier principle |

| Introduction of every parts |

| UHP wear parts replacement |

| Elimination HP normal troubles |

| HP cutting water and cooling water requirement |

| HP on/off valve , cutting head and abrasive controller maintenance |

| Drawing designing and programming |

| Software operating ,parameters setting and saving |

Verpackung & amp; Versand

goldener Lieferant

FAQ

| WHY US? |

| 1. High quality |

| The components we use is from high level suppliers, which can guarantee the stable working and long life use time. |

| The no troubleshorting working time can be over 1000 hours Can guarantee the cutting accuracy |

| 2. Easy operation |

| Professional water cutting machine software, no need G code program, you only need to know the use of AUTOCAD |

| 3. New function development |

| We work to develop new products to update the function of machine, for short time, we reserch the loading system, |

| height tracking system, wireless handle, four-axis cutting head. |

| 4. Favorable spare parts price and supply on time. |

| When your machine need spare parts to work, we will act quickly, and guarantte the machine work continuously. |

| 5. After sale service |

| Professional service team and 24 hours online to solve your problems, give quick and professional guide. |

Produktgruppe : Stein und Marmor Schneidemaschine

Premium Related Products