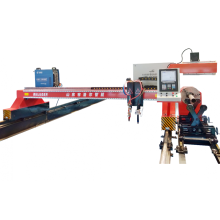

HEAD Marke Abrasive Jet Maschine Wasserstrahl Schneiden Metall Maschine

- Verpakung:

- Weiches Paket oder andere von beiden Seiten ausgehandelt Schleifmittelstrahl Wasserstrahl Schneidmetall

- Marke:

- KOPF

- Ort Von Zukunft:

- Liaoning, China (Festland)

- Versorgungsmaterial-Fähigkeit:

- 20 Set/Sets per Month Abrasive jet machine Waterjet Cutting metal

Basisinformation

Modell: HEAD3020BA/HEAD38030Z

Produktbeschreibung

| As per rich cutting experience , we recommend sheet metal fabrication adapt HEAD3020BA/HEAD38030Z with 3000x2000mm cutting table and 380Mpa intensifier pump . |

Produktbeschreibung

| Main technical parameter of Abrasive jet machine Waterjet Cutting metal | ||

| Intensifier Pump | Item | Parameter |

|

Model | HEAD38030Z |

| Brand | ACCUSTREAM from USA | |

| Method of Direction Regulation | Electronic Direction Regulation | |

| Pressure Range | 380MPA | |

| Maximum Flow of Hydraulic Pump | 90L/min | |

| Maximum Discharge Capacity | 3.7L/min, 3.8L/min | |

| Maximum Diameter of Gem Nozzle | 0.3mm,0.33mm | |

| Power of Master Motor | 30KW(40Hp) | |

| Power Source | 380V/50HZ | |

| Cutting Table | Item | Parameter |

|

X axis characteristic | Adapting the one-off extrusion forming aluminum alloy |

| Y axis characteristic | Cast iron used as foundation base | |

| Z axis characteristic | Z axis double linear guide and four sliding block | |

| Driving system | Z axis automatic controll,3 axis association processing | |

| Ball screw,linear guide | ABBA Taiwan | |

| Table structure | Separated body | |

| Driving way | Servo drive system | |

| CNC system | Ncstudio ,Fagor | |

| Servo motor | YASKAWA/FUJI | |

| Cutting head | Casting structure and concrete structure | |

| Sealing way | Whole piece sealing,cancelling dustproof cloth on X,Y,Z axis | |

| Loading weight water tank | Wall thickness is 5mm,using fluorocarbon coating | |

| CNC Controller | Item | Parameter |

|

Control Method | CNC |

| Display Size | 19inch LCD | |

| Model of Cutting Text | DXF | |

| Model of Computer | Industrial Control Computer | |

| Operating System | Windows XP/7 | |

| PLC | OMRON | |

| Cutting software advantage | Auto save and transfer common parameter | |

| Controller displace | Can be fit to suitable place at own will | |

| Automitic Abrasive Feeder | Item | Parameter |

|

Founction | Sand storage and sand delivery |

| Operating | No need electrocnic control,sample operation | |

| Capacity | 200 liters for 8 hours | |

| Pressure | Less than 0.2Mpa compresses gas pressure | |

| Level | Standard equipment of HEAD waterjet | |

| Color | White | |

| Deionization System | Item | Parameter |

|

Water pressure | 0.15Mpa~0.6Mpa |

| Water temperature | 5°C~50°C | |

| Environment temperature | 5°C~50°C | |

| Relative humidity | ≤95%(25°C) | |

| Water turbidity | <20FTU | |

| Wireless Handel | Item | Parameter |

|

Founction | Wireless controlling waterjet |

| Display | Real- time display condition of X,Y,Z axis | |

| Settings | Zero point, on/off valve set, X,Y,Z axis moving | |

| Technology | Advanced technology | |

Verpackungen & amp; Versand

package delivery process Abrasive jet machine Waterjet Cutting metal |

Unsere Leistungen

Dienstleistungsverpflichtung

After-sale service of Abrasive jet machine Waterjet Cutting metal | |

UHP Intensifier principle |

Introduction of every parts |

Wear parts replacement |

Elimination of normal troubles |

Table maintenance |

On-off valve, cutting head maintenance |

Abrasive controller maintenance |

Drawing designing and programming |

Software operating |

Parameters setting and saving |

Equipment operating | |

7-day to 10-day operating & maintenance training period | |

Warranty shall remain within 12 months since the date that assembly | |

Kundenbesuch Wasserstrahl Schneiden Metall Prozess Maschine Metallschneider Kunden besuchen

WIR WERDEN FÜR IHRE KOMME INSTALLIEREN

DAS DRITT-INSPEKTIONS-UNTERNEHMEN IST FÜR UNSER KOPF ANNEHMBAR.

Häufig gestellte Fragen

| WHY US? |

| 1. High quality |

| The components we use is from high level suppliers, which can guarantee the stable working and long life use time. |

| The no troubleshorting working time can be over 1000 hours Can guarantee the cutting accuracy |

| 2. Easy operation |

| Professional water cutting machine software, no need G code program, you only need to know the use of AUTOCAD |

| 3. New function development |

| We work to develop new products to update the function of machine, for short time |

| 4. Favorable spare parts price and supply on time. |

| When your machine need spare parts to work, we will act quickly, and guarantte the machine work continuously. |

| 5. After sale service |

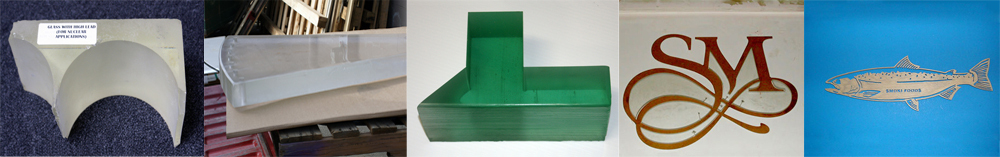

Mit Ausnahme von Metallschneiden kann Wasserstrahl auch Glas, Stein, Gummi und Kunststoffschneiden realisieren.

Produktgruppe : Bridge-Serie für Schneidemaschine

Premium Related Products