Neue Art cnc Schneidemaschine Wasserstrahlschneidemaschine

- Verpakung:

- Cnc Schneidemaschine weiche Verpackung oder nach Ihrer Anfrage.

- Marke:

- Kopf

- Ort Von Zukunft:

- Liaoning, China (Festland)

- Versorgungsmaterial-Fähigkeit:

- 15 Set/Sets per Month water jet cutting machine

Basisinformation

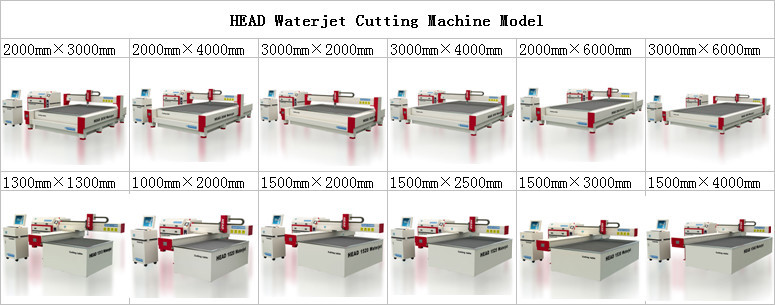

Modell: 380series

Produktbeschreibung

2.hydraulischen Druck

3.precision Arbeit

4. Kaltschneiden

5.Kurve Schneiden

Kopf Wasserstrahl Schneidemaschine:

Dieser Wasserstrahl hat hohe Energie und es kann weiche Materialien wie Papier, Gummi, Schwamm, etc. schneiden. Darüber hinaus, wenn gemischte richtige Menge Schleifmittel, kann es schneiden alle Arten von weichen und harten Materialien wie Glas, Marmor, Keramik, Edelstahl, Etc.

Wasserstrahlschneidemaschine Schneidproben:

Produktbeschreibung

Main technical parameter of waterjet cutting machine | ||||||||

| ||||||||

Intensifier Pump | ||||||||

1.Pumps are imported from American Accustream company with advanced & reasonable structure and high stability. | ||||||||

2. Integrated heat exchanger, high heat exchange ratio and good effect, control the temperature of the hydraulic oil within the limit | ||||||||

3. Two-stage water filter(5um,1um,0.45um)minimizes the damage of impurities to high pressure seals, nozzles and other parts. | ||||||||

4.Two step-up water supply to make sure the pressure, automatic alarm and protection function when water is inadequate avoid the damage | ||||||||

5.Multiple filter for outlet oil and return oil, pollution alarm, oil cooling and oil temperature alarming ensure the continuous operation | ||||||||

6.Flexible connection between the main motor and pump eliminates eccentricity and absorbs vibration to ensure its long-term reliable operation. | ||||||||

7. Large capacity accumulator, assuring the system pressure much more stable, cutting efficiency much higher | ||||||||

Model |

HEAD42037Z |

|||||||

Intensifier |

USA imported |

|||||||

Method of Direction Regulation |

Electronic Direction Regulation |

|||||||

Max cutting pressure |

420MPA |

|||||||

Continuous working pressure |

370-390Mpa |

|||||||

Max oil pressure |

21Mpa |

|||||||

Max water discharge |

3.8L/min |

|||||||

Max oil discharge |

106L/min |

|||||||

Power Source |

380V/50HZ |

|||||||

Max diameter of orifice |

0.35mm |

|||||||

accumulator capacity |

1.2L |

|||||||

The oil pump type |

Automatic variable hydraulic pump |

|||||||

Cutting Table | ||||||||

1. Separate body between cutting table and load-bearing platform prevents interfering cutting accuracy. | ||||||||

2.X beam of cutting table applies the one-off extrusion forming aluminum alloy, light weight, strong steel, not deformed. | ||||||||

3. Cancelling dustproof cloth on X, Y, Z axis and hiding Y axis towline greatly improve the machine life and save the maintenance cost. | ||||||||

4. Motor and ball screw are directly connected by flexible coupling. It can absorb vibration energy reversible and with higher drive accuracy. | ||||||||

5. Using high-quality international brand ball screw, linear guide transmission structure to ensure the moving speed and accuracy. | ||||||||

Item |

Character |

|||||||

Machine type |

Bridge style and Cantilever style |

|||||||

Way of drive |

Servo drive( drives and motors are Yaskawa brand from Japan |

|||||||

Ball screw and linear guide |

ABBA brand from Taiwan |

|||||||

Processing range: |

Bridge style: X axis 2000mm-30000/ Y axis 2000mm-6000mm |

|||||||

|

Cantilever style: X axis 1000mm-1500 Y axis 2000mm-4000mm |

|||||||

Z-axis travel journey |

150mm |

|||||||

Controlling accuracy |

0.01mm |

|||||||

Cutting accuracy |

0.1mm |

|||||||

Re-position accuracy |

0.02mm |

|||||||

Max traveling speed |

6000mm/min |

|||||||

| ||||||||

CNC Controller | ||||||||

1. Industrial control computer: high reliability, convenient man-machine dialogue, real-time control of the cutting process | ||||||||

2. CNC control, apply 19 inch LCD. facilitate operators to observe and reduce visual fatigue. | ||||||||

3.Appropriate height of operating desk, reasonable display angle, and 180-degree horizontal rotation for easy operation and viewing | ||||||||

4. Replace the relay with PLC, with a computer communications, flexible control | ||||||||

5. Professional waterjet cutting software, easy to operate , easy to learn, and practical. | ||||||||

6. Support DXF file ,can use AUTOCAD to produce DXF file | ||||||||

7. use IPC and the professional software based on windows XP | ||||||||

Accessory and optional Items | ||||||||

Automitic Abrasive Feeder |

Advantages |

|||||||

|

1. Can supply the cutting sand quantity according to the adjustable sand level location tube |

|||||||

2. No need electronic control, simple operation, reliable, maintenance-free | ||||||||

3. 200liters capacity can provide enough sand for 8 hours continuous cutting | ||||||||

4. Need less than 0.2Mpa compressed gas pressure,sand amount evenly, delivery smooth | ||||||||

5. It is the standard components of HEAD water jet | ||||||||

Deionization System |

Advantages |

|||||||

|

1. Professional deionization system for water jet use |

|||||||

2. Remove the calcium and magnesium ion, can improve the useful life of HP seals, orifice | ||||||||

3. The outlet water amount can be 2ton/hour,can supply more than one machine | ||||||||

4. Simple structure and reliable sealing, reasonable design of the flow passage | ||||||||

5. Single tank control valve,no water pass the valve in washing | ||||||||

Wireless remote control handle |

Advantages |

|||||||

|

1. WHB06 the wireless remote control handle special design for HEAD waterjet control system |

|||||||

2. It can realize wireless controlling water jet and long-distance materials processing | ||||||||

3. With display function,real-time display X.Y.Z axis workpiece coordinate, mechanical coordinate,speed,step value. | ||||||||

4. Can set workpiece zero ,back to zero point, back to mechanical zero point,feed speed adjusting | ||||||||

5. Adapt high performance wireless transmission technology,frequency hopping transmission. | ||||||||

Oil chiller |

Advantages |

|||||||

|

1. Professional oil chiller for water jet use |

|||||||

2. Main motor adapts newest imported compressor, safety in operation, high efficiency, lower noise | ||||||||

3. Imported brand oil pump, higher pressure, higher stability, long term durability | ||||||||

4. Imported digital controller,high accuracy, wide use range | ||||||||

5. Can control the oil temperature in any range, can work well under 45 degree surroundings. | ||||||||

Auto height tracking and following system |

Advantages |

|||||||

|

1. For big size metal sheet which will have surface irregularity during cutting |

|||||||

2. Can protect the nozzle broken by collision during cutting | ||||||||

3. System can control the distance between cutting head and workpiece | ||||||||

4. Reduce the manual set tool and mistake | ||||||||

5. A very new update for cutting | ||||||||

Auto abrasive removal system |

Advantages |

|||||||

|

1. Automatic desanding system is specifically designed for high-end customers. |

|||||||

2. Automatic desanding system can automatically deliver the mixture of sand and water in the water tank | ||||||||

3. It can make maximize savings in manpower and extend the usage life for equipment | ||||||||

4. Keeping the least content of sand in the water tank | ||||||||

5. Maximum keeping the cutting environment clean. | ||||||||

FAST CAM nesting software |

Advantages |

|||||||

|

1. Professional optimization nesting engine with a variety of ways and means of optimizing nesting |

|||||||

2. Multiple formats for file of nesting, including DXF, DWG, CAM and NC. | ||||||||

3.Single or bulk reading or importing files for fast automatic nesting | ||||||||

4. Setting parts line row, list row or matrix for automatic nesting. | ||||||||

5. Editing the remaining plates, as well as nesting the remaining plates or irregular plates | ||||||||

Update cutting solution- dynamic cutting head to protect the complete vertical cutting | ||||||||

1.HEAD 5-axis, simple structure, small volume,light weight,high precise | ||||||||

2.750w Japan YASKAWA servo,high power,high precise,fast corner speed,perfect walking curve | ||||||||

3.Adopt mini-type high precise Omron proximity sensor,high positioning accuracy ,fast induction | ||||||||

4.Newest dust proof structure design,make sure that the rotational system,slide system is inclusion-free | ||||||||

5.equipped with the Japan imported bearings,all these improve the using life,guarantee the motivation precise | ||||||||

6.Adopted the domestic most advanced water jet 5 axis cutting software,strong function and good cutting result | ||||||||

7.Manually adjust the angle of the cutting head,the precision is between ±6°,assure the best cutting quality in any case. | ||||||||

| ||||||||

Inspektion Um sicherzustellen, dass HEAD Waterjet Schneidemaschine gut laufen kann, haben unsere Techniker eine Reihe strenger Inspektion vor dem Versand gemacht, wir verwenden die genauesten und fortschrittlichsten Prüfgeräte, so dass HEAD Waterjet Schneidemaschine den internationalen Standard erreichen kann, um den Anforderungen der verschiedenen Kunden gerecht zu werden.

Unsere Dienstleistungen Ingenieure zur Verfügung, um Maschinen in Übersee Wasserstrahl-Schneidemaschine

Technische Ausbildung:

1. UHP-Verstärkerprinzip

2. Einleitung aller Teile

3. Verschleißteile ersetzen

4. Beseitigung der normalen Schwierigkeiten

5. Tischpflege

6. Ein-Aus-Ventil, Schneidkopf und Abrasiv-Controller Wartung.

7. Zeichnung Design und Programmierung

8. Software Betrieb, Parametrierung und Speicherung

9. Betriebsmittel

Verpackung & amp; Versand HEAD Corporation: Weiche Verpackung, auf dem Seeweg, jeder Hafen, sicher und zuverlässig! Wasserstrahlschneidemaschine

Zertifizierungen

Wir haben mehr als 20 Arten von Modellen, willkommen zu Ihrem mehr Details Anfrage!

Finden Sie uns durch:

cnc Schneidemaschinen

Wasserstrahlschneidemaschine

Produktgruppe : Bridge-Serie für Schneidemaschine

Premium Related Products